Ölçek Mühendislik adds a new one to its successful works with “Pipe Deformation Analysis and 3D Model Studies with Laser Scanning Technology”.

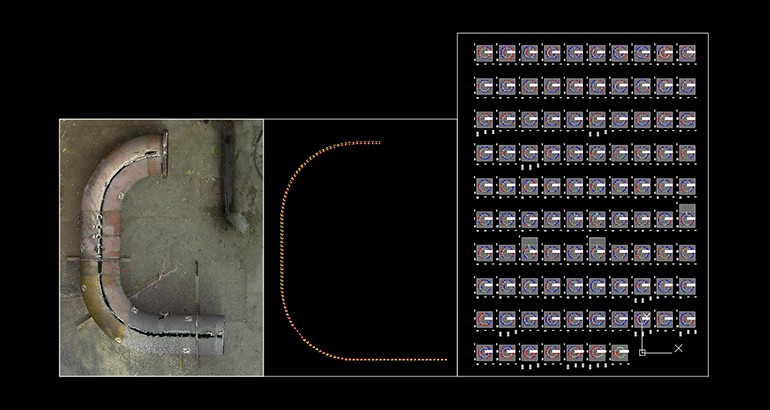

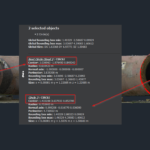

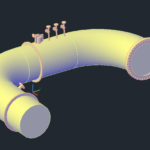

Laser scanning technology offers a highly effective method for deformation analysis in pipelines as well as flange fluctuation control. This technology creates 3D point clouds with high precision, and this data makes it possible to visualize deformations on the pipe surface through heat maps. The heat map represents the intensity of deviations on the pipe with colors, allowing critical areas to be quickly identified.

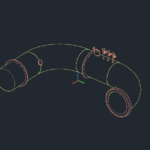

In addition, creating cross-sections along the pipe route is an important step to assess the structural integrity of the pipe and identify potential risk areas. These cross-sections are integrated with CAD software, providing a detailed analysis of the pipeline. Since fluctuations, especially at flange connection points, can cause pressure differences and material fatigue, these areas need to be checked in detail with laser scans.

As a result, these analyses performed with laser scanning technology are of critical importance to ensure the safety of pipelines and prevent potential failures.